Stage 1

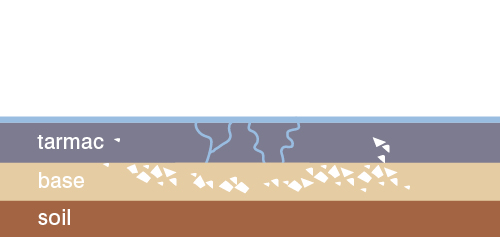

Water seeps in through cracks in the road surface, collecting underneath.

Complete the National Highways and Transport survey and tell us what you think about how the highways are maintained in Lancashire.

Our highways inspectors regularly check major roads and footways for defects.

They walk or drive:

If you see a pothole marked out in white paint, it means our inspector has assessed that it meets our levels to be fixed and will be repaired within our standard response times.

We need your help in reporting potholes to us. If you spot any potholes in between our inspections that could cause a safety risk, use our online Report It website or our Love Clean Streets mobile app.

We aim to fix 90% of reported potholes within 20 days.

Watch our video below which explains how to report a pothole via our Report It website .

The following stages demonstrate how a combination of weather and wear and tear is one of the major causes of potholes on roads.

We aim to repair potholes with the right type of repair, first time.

Sometimes for the safety of road users, temporary repairs are made until a permanent repair can be carried out. This might be because the repair location requires complex traffic management or because of adverse weather conditions.

Pothole repairs can vary from small individual repairs to larger patched repairs.

As well as traditional methods, we use several innovative approaches to ensure that repairs are carried out quickly, cost effectively and with minimal waste.

Here are examples of how we carry out the spray injection process and mechanical repair process.

This is also known as jet patching which gives long lasting results on rural roads. Jet patching is a fast, 4 stage pothole repair process:

This is a 3 stage process:

Watch our video below to see our highways engineers answer your common questions about potholes. You can also watch the series of videos from our Highways Team, which explain more about how we maintain our roads in Lancashire.